MicroUPS |

|

09/91 to 02/94 |

|

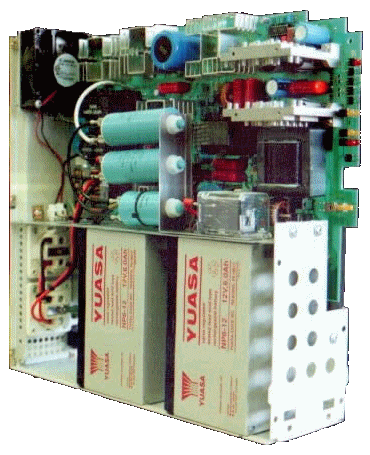

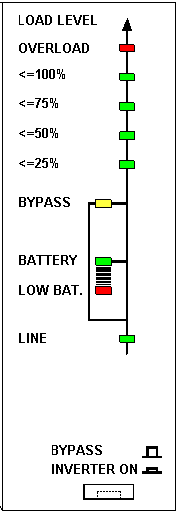

An Uninterruptible Power Supply (UPS) in three ratings: 0.5, 1.0 and 2.0kVA,

the MicroUPS together with the MiniUPS, 3.0, 5.0, 7.5 and 10kVA, was designed

over two years as a complete UPS range to be sold worldwide. The range replaced a badged product with a large existing customer base and production quantities of 20,000 per annum anticipated. I designed a common control system for the entire UPS range. This included design of the system functionality, requiring a broad range of knowledge from power electronics to ASIC design. |

|

|

Choosing the best trade-off between hardware and software functions, the control system

was realised around a microprocessor and ASIC core, utilising a technique called,

'Direct Digital Synthesis'. In order to minimise risk and NRE charges, the ASIC implementation was first realised in a FPGA. |

|

This

was a new technology to our department.

Responsible for the justification, selection, and maintenance of the CAD tools required,

I choose Xilinx - mostly for their RAM based architecture as this allowed for design iterations without

consuming what at the time were expensive FPGA parts. This

was a new technology to our department.

Responsible for the justification, selection, and maintenance of the CAD tools required,

I choose Xilinx - mostly for their RAM based architecture as this allowed for design iterations without

consuming what at the time were expensive FPGA parts.I also invested in PSpice simulation software, which the whole design team utilised to verify the functionality of the MicroUPS. In addition, we were able to use the 'Monte Carlo' feature to perform statistical analysis. Using this feature I was able to show that where 'worst-case' design would have indicated the use of tight tolerance components, in many cases, we could avoid this. This resulted in lower material cost, and increased competitive advantage. I wrote the production test specification for the product and undertook a comprehensive Type Test programme prior to release for manufacture. |

|